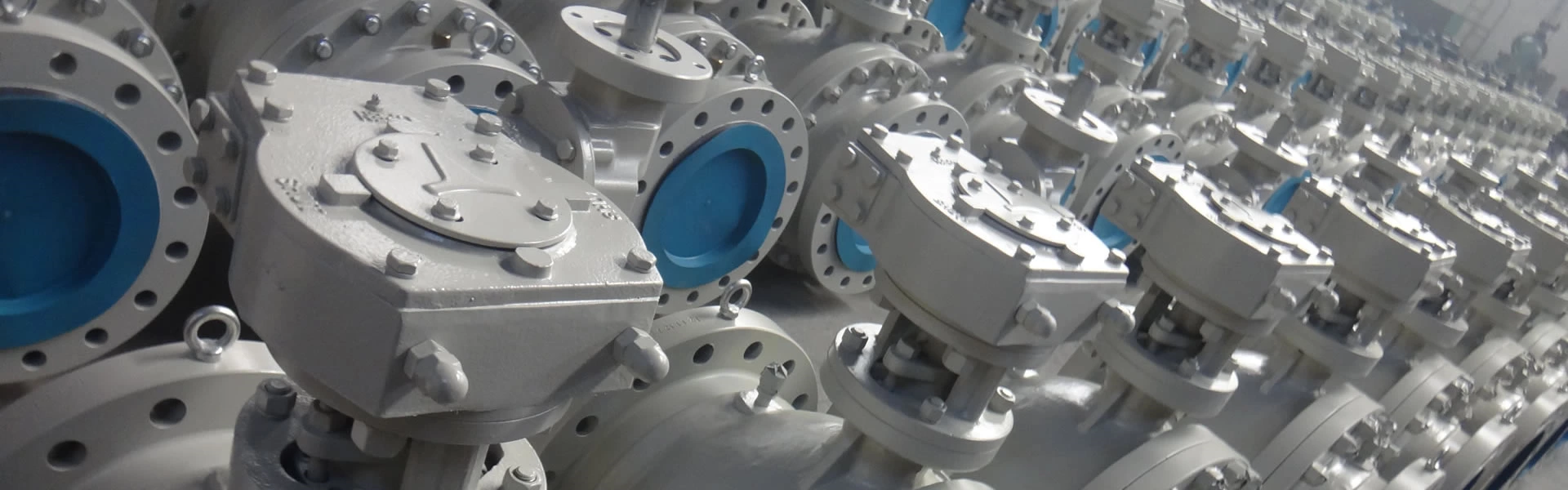

Steam Globe Valve

- Size Range

- NPS1/ 2′′~NPS 16′′ DN15-DN400

- Temperature Range

- -29~550°C

- Pressure Rating

- CLB150~CL2500 PN10~PN420

Specification Parameters

| Name | Steam globe valve |

| Size | NPS1/ 2′′~NPS 16′′ DN15-DN400 |

| Pressure | CLB150~CL2500 PN10~PN420 |

| Temperature | -29~550°C |

| Body Material | Stainless steel 304.316, cast steel |

Design Standards

| Design and Manufacturing Standards | ASME B16.34, API6D |

| Structure length | ASME B16.10 |

| Flange end size | ASME B16.5 |

| Threaded end size | ANSI B1.20.1 |

| Terminal end size | ANSI B16.25 |

| socket size | ANSI B16.11 |

| Test and Test | API598 |

Design Standard:

| Design and Manufacturing Standards | DIN3356 |

| Structure length | DIN3202 |

| Flange end size | DIN2543-2545 or optional |

| Terminal end size | DIN3239 |

| Test and Test | DIN3230 |

Product introduction

Steam globe valve use:

Trained steam shut-off valve (also known as "bellows seal globe valve"), this valve introduces foreign advanced technology, adopts double-layer bellows design, welds to the valve stem to maintain stable running performance, avoids valve caused by valve plug vibration The rod vibrates. At high temperatures, the steam stop valve does not come into contact with the media, ensuring zero leakage of the valve stem. At the same time ensure sufficient strength and toughness, you can switch tens of thousands of times. The handwheel is ergonomically designed for longer life and easy operation. The opening and closing member of the steam shut-off valve is a plug-shaped valve flap. The sealing surface is flat or tapered. The valve flap moves linearly along the center line of the fluid. It is also called a door. It is the most widely used valve. It is popular because the friction between the sealing surfaces is small during the opening and closing process, it is relatively durable, the opening height is not large, the manufacturing is easy, and the maintenance is convenient. It is not only suitable for medium and low pressure, but also suitable for high pressure. It is widely used in food, medicine, petroleum, chemical, natural gas, steel, environmental protection, papermaking and other transportation pipelines to cut or circulate media.

Product advantages:

1. Reasonable product structure, reliable sealing, excellent performance and beautiful appearance;

2, Co-based cemented carbide surfacing, wear-resistant, corrosion-resistant, anti-friction performance, long service life;

3. Stem quenching and surface nitriding treatment, good corrosion resistance and anti-friction performance;

4, double seal, more reliable performance, zero leakage;

5, stem lift position indication, more intuitive;

6. Parts material, flange and butt weld number can be selected according to actual working conditions or user requirements to meet various engineering needs.

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China