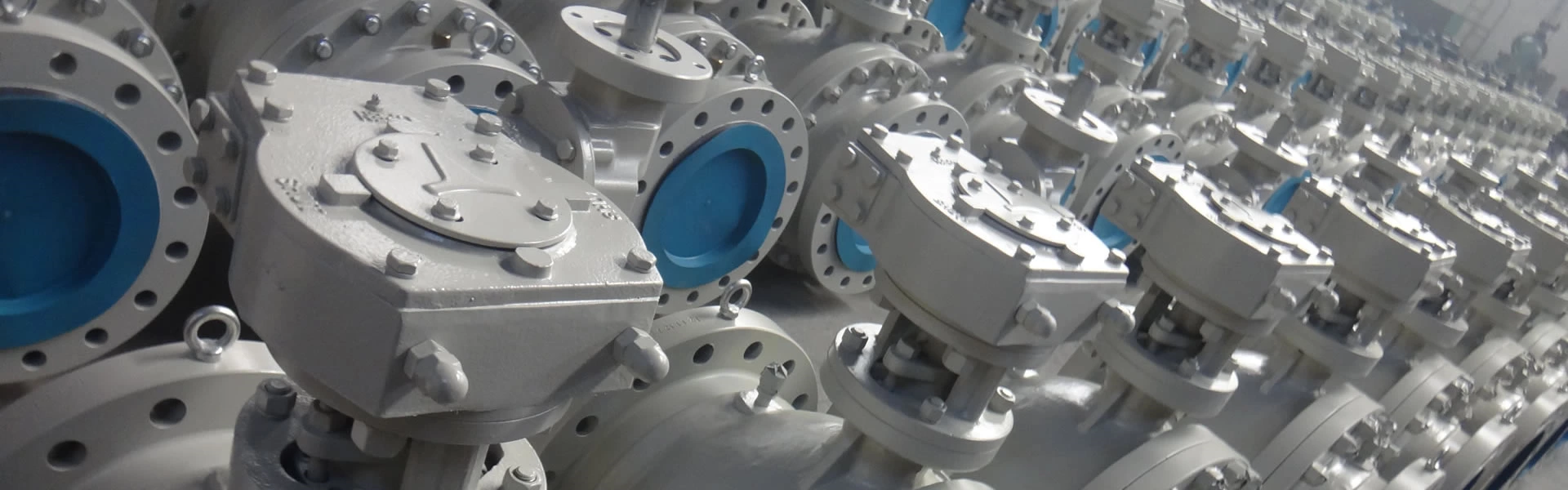

Stainless Steel Globe Valve

- Size Range

- NPS1/ 2′′~NPS 16′′ DN15-DN400

- Temperature Range

- -29~550°C

- Pressure Rating

- CLB150~CL2500 PN10~PN420

Specification parameters

| Name | Stainless steel globe valve |

| Size | NPS1/ 2′′~NPS 16′′ DN15-DN400 |

| Pressure | CLB150~CL2500 PN10~PN420 |

| Temperature | -29~550°C |

| Application | Water, sewage, construction, petroleum, chemical, food, pharmaceutical, textile, electric power, shipbuilding, metallurgy, energy systems |

| Body Material | Stainless steel 304, 304L, 316, 316L |

Design Specification

| Design and Manufacturing | API 6D, ANSI B 16.34 or BS 1873 |

| Structure length | ANSI B 16.10 |

| Flange Standard | ANSI B 16.5a |

| Terminal end size | ANSI B 16.25 |

| Pressure test | API 6D or API 598 |

| pressure and temperature rating | ASME B16.34, GB/T 12224 |

Product introduction

Stainless steel globe valve is suitable for pipelines of various working conditions such as petroleum, chemical, hydraulic, thermal power stations, etc., cutting or connecting the medium. Applicable medium: water, oil, steam, etc. The operation modes are: manual, gear transmission, electric, etc.

Structural characteristics of stainless steel globe valve

1. The product meets the requirements of American national standard ANSI B16.34, British BS1873 and other foreign advanced standards.

2. The sealing surface of the valve disc and valve seat is made of hard alloy surfacing or body processing. It is wear-resistant, high temperature resistant, corrosion resistant, good scratch resistance and long service life.

3. The valve stem is quenched and tempered and has good corrosion resistance and scratch resistance.

4. Various pipe flange standards and flange sealing surface types can be used to meet various engineering needs and user requirements.

5. The valve body material is complete, and the packing and gasket are reasonably matched according to the actual working conditions or user requirements, and can be applied to various pressure, temperature and medium working conditions.

API Globe Valve Reference Standard

Design and Manufacturing: API 6D, ANSI B 16.34 or BS 1873

Structure length: ANSI B 16.10

Flange Standard: ANSI B 16.5a

Terminal end size: ANSI B 16.25

Pressure testing: API 6D or API 598

American Standard Stop Valve Use

API globe valve is suitable for pipelines of various working conditions such as petroleum, chemical, hydraulic, thermal power stations, etc., cutting or connecting the medium. Applicable medium: water, oil, steam, etc. The operation modes are: manual, gear transmission, electric, etc.

Structural Features

1. The product meets the requirements of American national standard ANSI B16.34, British BS1873 and other foreign advanced standards.

2. The sealing surface of the valve disc and valve seat is made of hard alloy surfacing or body processing. It is wear-resistant, high temperature resistant, corrosion resistant, good scratch resistance and long service life.

3. The valve stem is quenched and tempered and has good corrosion resistance and scratch resistance.

4. Various pipe flange standards and flange sealing surface types can be used to meet various engineering needs and user requirements.

5. The valve body material is complete, and the packing and gasket are reasonably matched according to the actual working conditions or user requirements, and can be applied to various pressure, temperature and medium working conditions.

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China