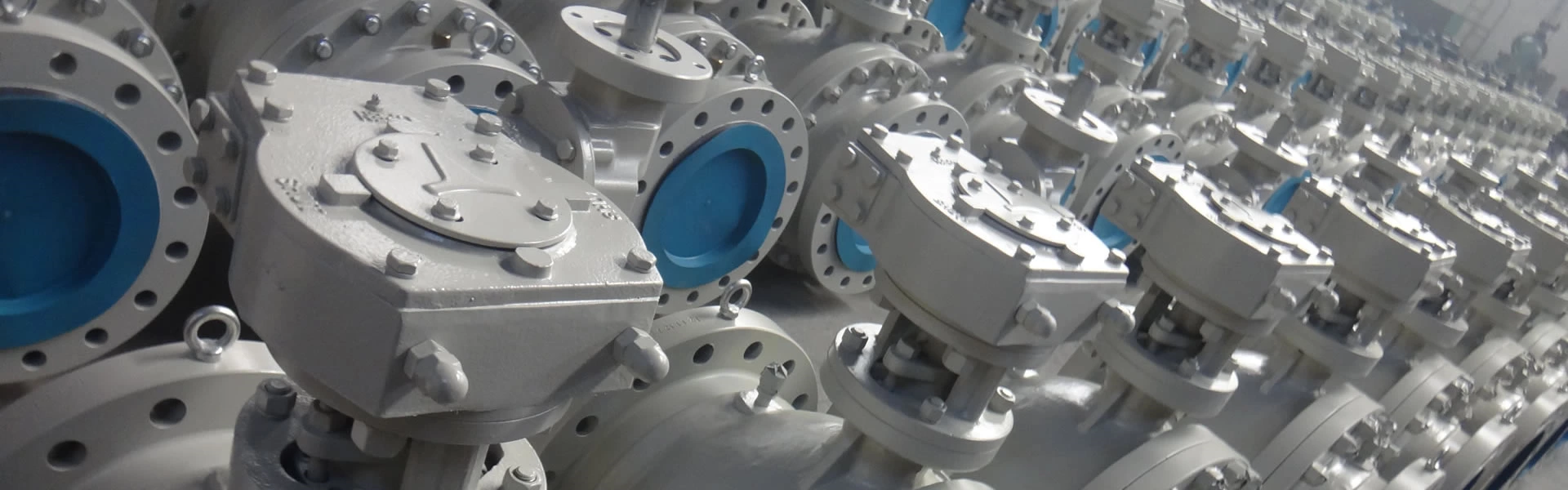

Forged Steel Globe Valve

- Size Range

- NPS1/ 2′′~NPS 2′′ DN11-DN50

- Temperature Range

- -29~550°C

- Pressure Rating

- CLB150~CL2500 PN10~PN420

Specification Parameters

| Name | Forged Steel Globe Valve |

| Size | NPS1/ 2′′~NPS 2′′ DN11-DN50 |

| Pressure | CLB150~CL2500 PN10~PN420 |

| Temperature | -29~550°C |

| Application | Applicable to various media such as water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea, etc. |

| Body Material | A105/F304/F11 |

Design Specification

| Design and Manufacturing | API 6D, ANSI B 16.34 or BS 1873 |

| Structure length | ANSI B 16.10 |

| Flange Standard | ANSI B 16.5a |

| Terminal end size | ANSI B 16.25 |

| Pressure test | API 6D or API 598 |

| pressure and temperature rating | ASME B16.34, GB/T 12224 |

Product Introduction

The most obvious advantage of the forged steel globe valve is that during the opening and closing process, the friction between the valve disc and the sealing surface of the valve body is smaller than that of the gate valve, so it is wear-resistant. The opening height is generally only 1/4 of the diameter of the seat channel and therefore much smaller than the gate valve. Usually there is only one sealing surface on the valve body and the valve flap, so the manufacturing process is better and easy to repair.

Drive mode: manual, bevel gear transmission, pneumatic, electric, hydraulic, gas-liquid linkage, electro-hydraulic linkage, flange connection, socket, thread, butt weld connection, etc.

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China