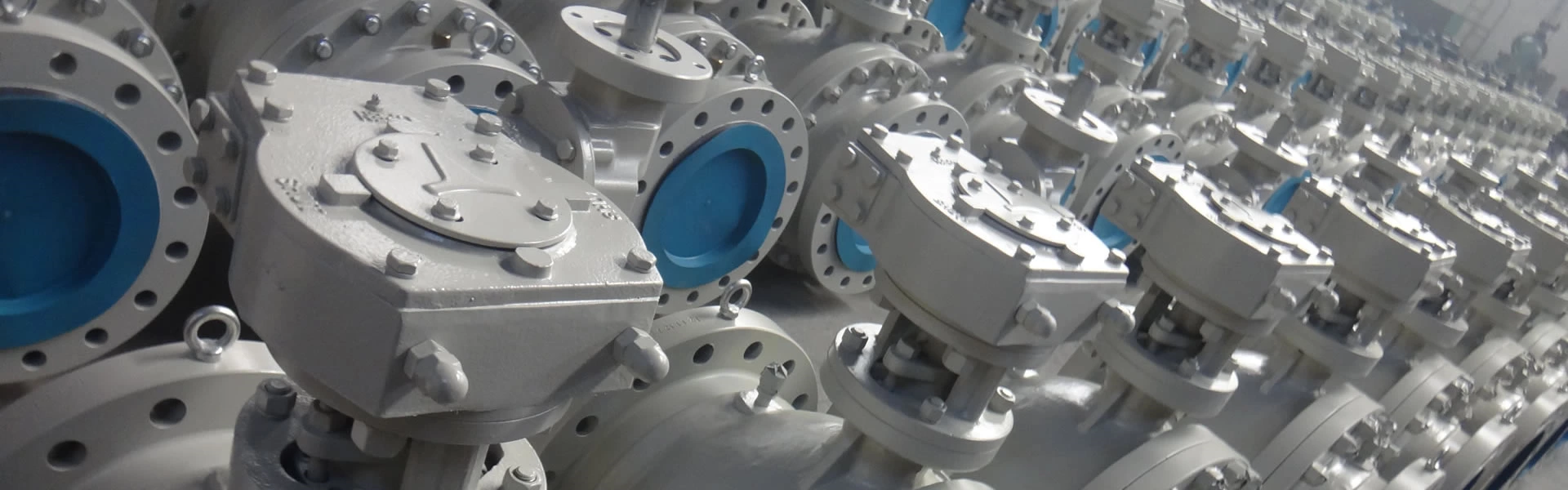

Gas Gate Valve

- Size Range

- DN25-1000, 1"-40"

- Temperature Range

- -29~121°C

- Pressure Rating

- Class 15LB-600LB, PN0.6~6.4MPa

Specification parameters

| Name | Gas Slab Gate Valve |

| Size | DN25-1000, 1"-40" |

| Pressure | PN0.6~6.4MPa, 15-600LB |

| Temperature | -29~121°C |

| Body Material | carbon steel, stainless steel, alloy steel |

Design Specification

| Design Standards | API 6D, ASME B16.34, GB/T 19627 |

| Structure length | ASME B16.10, GB/T 12221 |

| Connection Standard | ASME B16.5, GB/T 9113, JB/T 79 |

| Pressure test | API 6DS, GB/T 13927, GB/T 26480, JB/T 9092 |

| pressure and temperature rating | API 6D, GB/T 26480 |

Product Description

gas slab gate valve, the gas gate valve independently developed by our factory is reliable in quality and suitable for all kinds of light and heavy industry and building pipelines. Gas slab gate valves are widely used in: chemical, petrochemical, petroleum, paper, mining, electric power, liquefied petroleum gas, food, pharmaceutical, water supply and drainage, municipal, mechanical equipment, electronics industry, urban construction and other fields.

Product structure features:

1 valve body is cast structure.

2 valve seat adopts O-ring seal and pre-tightening floating seat structure to make the valve inlet and outlet bidirectionally sealed; and the opening and closing torque of this structure is only 1/2 of ordinary valve, which can be easily opened Close the valve.

3 seat is made of PTFE on the sealing surface, with double sealing of PTFE to metal and metal to metal. PTFE sealing surface also removes the dirt of the gate.

The gate of the 4 valve, whether fully open or fully closed, always conforms to the sealing surface, and the sealing surface is protected from direct rubbing of the medium, thus prolonging the service life.

5 When the valve is fully open, the channel is smooth and straight, the flow resistance coefficient is very small, no pressure loss, and the pipeline can be cleaned by the ball.

6 When the valve is closed, the internal cavity high pressure can be automatically removed (see the working principle diagram for details) to ensure safe use.

7The closed gear is used to turn the opening and closing indication mechanism, which can clearly and clearly reflect the opening and closing of the valve for a long time.

8 The outer surface of the directly buried valve is treated with epoxy coal tar pitch for anti-corrosion treatment, which can last the same life as the pipeline.

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China