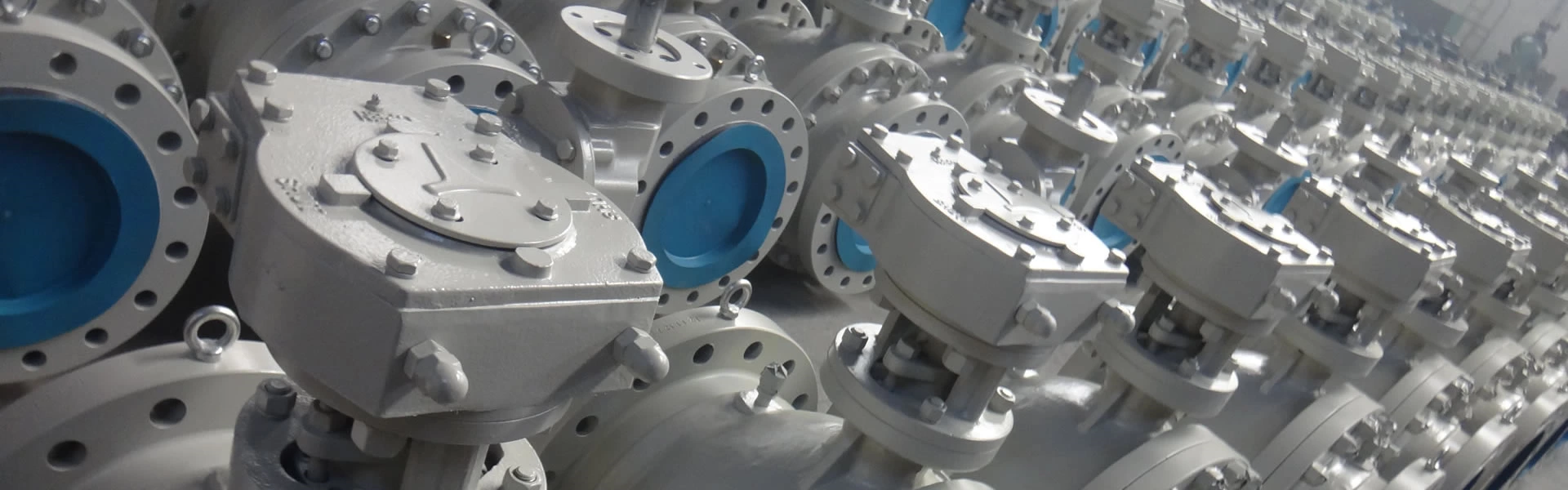

Flat Gate Valve

- Size Range

- NPS 2′′~NPS 48′′ DN50~DN120

- Temperature Range

- -29~121°C

- Pressure Rating

- CLB150~CL2500 PN10~PN420

Specification parameters

| Name | Flat gate valve |

| Size | NPS 2′′~NPS 48′′ DN50~DN1200 |

| Pressure | CLB150~CL2500 PN10~PN420 |

| Temperature | -29~121°C |

| Body Material | carbon steel, stainless steel, alloy steel |

Design Specification

| Design Standards | API 6D, ASME B16.34, GB/T 19627 |

| Structure length | ASME B16.10, GB/T 12221 |

| Connection Standard | ASME B16.5, GB/T 9113, JB/T 79 |

| Pressure test | API 6DS, GB/T 13927, GB/T 26480, JB/T 9092 |

| pressure and temperature rating | API 6D, GB/T 26480 |

Product Description

The flat gate valve is a slide valve in which the closing member is a parallel shutter. The closing member may be a single shutter or a double shutter with a distracting mechanism therebetween. The pressing force of the shutter to the valve seat is controlled by the medium pressure acting on the floating gate or the floating valve seat. In the case of a double gate slab gate valve, the expansion mechanism between the two shutters can supplement this pressing force.

features:

1. The valve seat adopts the O-ring seal and the floating valve seat structure with pre-tightening force to make the slab gate valve inlet and outlet bidirectionally sealed; and the opening and closing torque of the structure is only 1/2 of the ordinary valve, which can reach Open and close the valve easily

2. When fully open, the channel is smooth to a straight line, the flow resistance coefficient is very small, no pressure loss, and the pipeline can be cleaned by a hair ball

3. It adopts the packing structure with self-sealing ability, no need to adjust frequently, the opening and closing is extremely light, and the sealing is reliable. The packing letter is provided with auxiliary sealing grease injection structure, the sealing performance is absolutely reliable, and the zero leakage is truly achieved; Solved the shortcomings of the most common valve packing at the general valve packing

4. When the slab gate valve is closed, the internal cavity high pressure can be automatically removed to ensure safe use.

5, fully enclosed structure, good protection performance, can adapt to all-weather requirements

Slope gate valve application occasion

1. (Class 150~900/PN1.0~16.0MPa, working temperature -29~121°C) Oil and natural gas transmission pipeline. A slab gate valve with a diversion hole also facilitates cleaning of the line.

2. Conveying lines and storage equipment for refined oil.

3. Oil and gas production wellhead devices, that is, valves for oil trees.

4. Pipes with media with suspended particles.

5. City gas transmission pipeline.

6. Water supply works.

Platform gate valve selection principle

1. Oil and natural gas transmission pipelines, single-gate or double-grid slab gate valves. If it is necessary to clean the pipeline, use a single ram or double ram with a slab slab gate valve with a diversion hole.

2. For the pipeline and storage equipment of refined oil, use a single gate or double gate slab gate valve without a diversion hole.

3. Oil and gas production wellhead devices, single-gate or double-gate slab gate valves with diverted rod floating valve seat with diversion holes, mostly API 6A standard, pressure class API2000, API3000, API5000, API10000, API15000, API20000.

4. For pipes with suspended particle media, use a knife-type slab gate valve.

5. City gas transmission pipeline, single-gate or double-gate soft-sealed open-plate slab gate valve.

6. Urban water supply project, single-gate or double-grid without guide hole open-plate slab gate valve.

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China