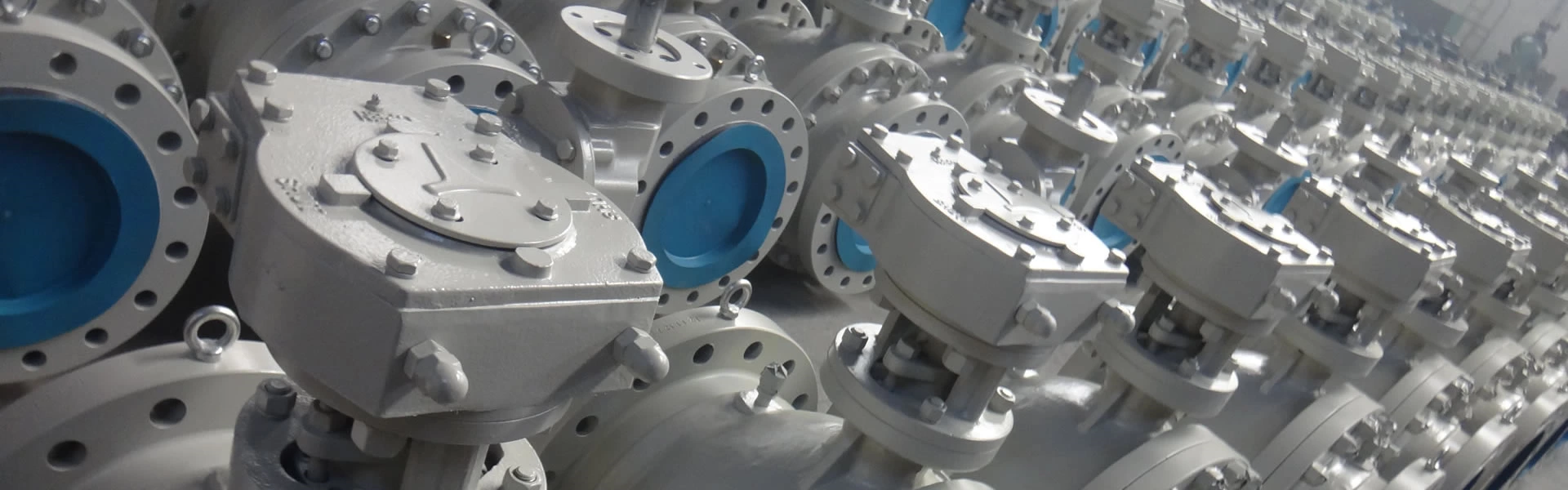

Swing Check Valve

- Size Range

- NPS1/ 2′′~NPS 16′′ DN15-DN400

- Temperature Range

- -20~350°C

- Pressure Rating

- CLB150~CL300 PN10~PN40

Specification Parameters

| Name | Swing Check Valve |

| Size | NPS1/ 2′′~NPS 16′′ DN15-DN400 |

| Pressure | CLB150~CL300 PN10~PN40 |

| Temperature | -20~350°C |

| Application | Water, sewage, construction, medicine, textile, electric power, shipbuilding, metallurgy, energy system |

| Body Material | Stainless steel 304, 316, cast steel |

Design Specification

| Design and Manufacturing | ANSI B 16.34 or BS 1873 |

| Structure length | ANSI B 16.10 |

| Flange Standard | ANSI B 16.5a |

| Terminal end size | ANSI B 16.25 |

| Pressure test | API 6D or API 598 |

| pressure and temperature rating | ASME B16.34, GB/T 12224 |

Product Description

The swing check valve acts to prevent backflow of media in the pipeline. The valve of the opening and closing member is opened or closed by the flow of the medium and the force to prevent the back flow of the medium from being called a check valve. Check valves are automatic valves, mainly used on pipes with one-way flow of media, allowing only the media to flow in one direction to prevent accidents. This type of valve should generally be installed horizontally in the pipeline. The check valve can be mainly divided into a swing type check valve (rotation according to the center of gravity) and a lift check valve (moving along the axis).

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China