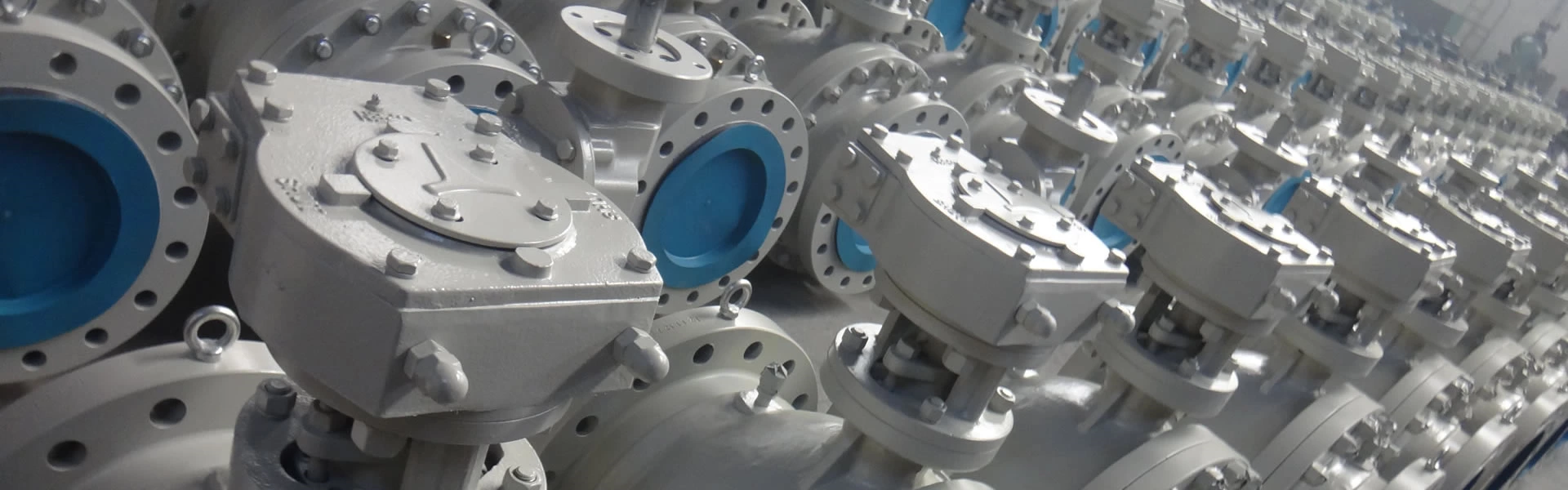

Cast Steel Check Valve

- Size Range

- NPS1/ 2′′~NPS 16′′ DN15-DN400

- Temperature Range

- -20~350°C

- Pressure Rating

- CLB150~CL300 PN10~PN40

Specification Parameters

| Name | Cast Steel Check Valve |

| Size | NPS1/ 2′′~NPS 16′′ DN15-DN400 |

| Pressure | CLB150~CL300 PN10~PN40 |

| Temperature | -20~350°C |

| Application | Oil, chemical, pharmaceutical, fertilizer, electricity and other pipelines |

| Body Material | Stainless steel 304, 316, cast steel |

Design Specification:

| Design and Manufacturing | ANSI B 16.34 or BS 1873 |

| Structure length | ANSI B 16.10 |

| Flange Standard | ANSI B 16.5a |

| Terminal end size | ANSI B 16.25 |

| Pressure test | API 6D or API 598 |

| pressure and temperature rating | ASME B16.34, GB/T 12224 |

Product Description

The cast steel check valve is an automatic valve type, and the opening and closing parts are opened or closed by the force of the flowing medium. The check valve is only used on the pipeline where the medium flows in one direction, preventing the medium from flowing back to prevent accidents. The check valve adopts a built-in rocker swinging structure, the valve flap rotates around the rotating shaft, the valve flap opens under the action of fluid pressure, and the fluid flows from the inlet side to the outlet side. When the inlet side pressure is lower than the outlet side, the valve flap automatically closes under the influence of fluid pressure difference, its own gravity and the like to prevent the fluid from flowing backward. The cast steel check valve can be mainly divided into a swing type check valve (rotation according to the center of gravity) and a lift check valve (moving along the axis).

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China