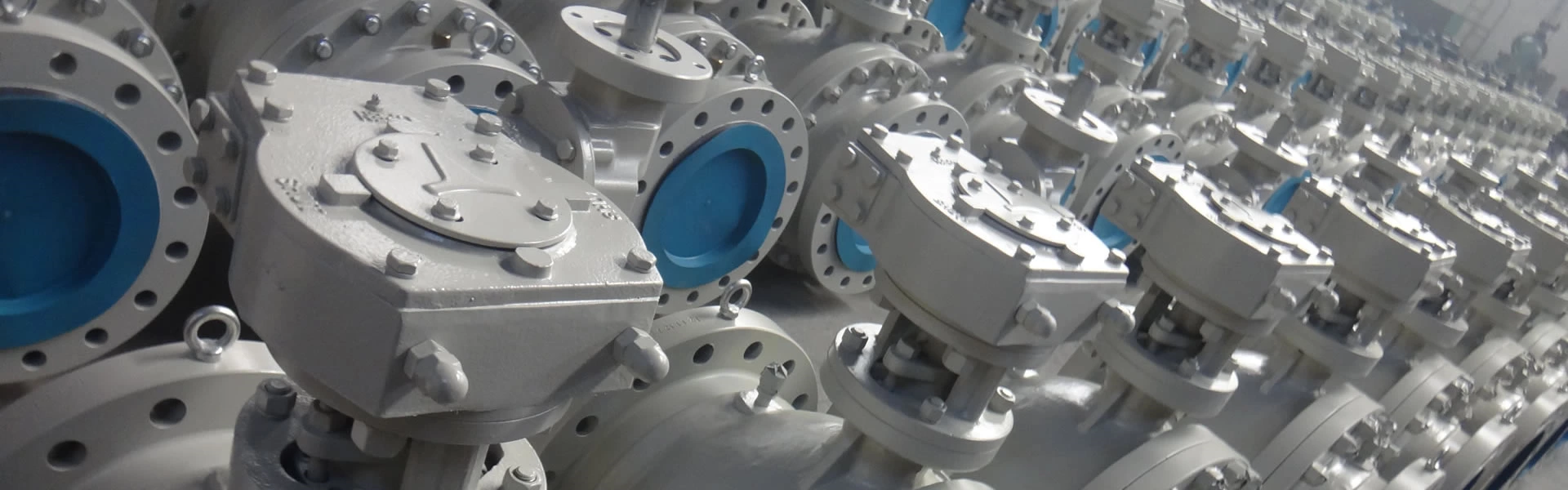

Ventilation Butterfly Valve

- Size Range

- 10LB (PN1~PN2.5)

- Temperature Range

- -20°C~+425°C

- Pressure Rating

- 10LB (PN1~PN2.5)

- Operation Type

- Electric, pneumatic, hydraulic, turbine, etc.

Specification parameters

| Name | Ventilation Butterfly Valve |

| Size | 2" ~ 120" (DN50~DN3000) |

| Pressure | 10LB (PN1~PN2.5) |

| Temperature | -20°C~+425°C |

| Drive Mode | Electric, pneumatic, hydraulic, turbine, etc. |

| Applicable Media | air, smoke, dust, etc. |

| Leak Rate | Normal type ≤2% Low leakage rate ≤1% |

Design Standards

| Design Standards | GB/T12238-1 989 JB/T8692-1998 |

| Flange connection size | GB/T9115.1-2000 |

| Structure length | GB/T1222.1989 |

| Pressure test | GB/T13927-1992;JB/T9092-1999 |

Product introduction

The ventilating butterfly valve is a regulating butterfly valve with simple structure, superior performance, high temperature resistance and corrosion resistance, and can also be used for switching control of low pressure pipeline media. The vented butterfly valve is a non-closed butterfly valve.

Ventilation butterfly valve is used in the dusty cold air or hot air gas pipeline of ventilation, environmental protection engineering in chemical industry, building materials, power station, glass and other industries. It is used as a gas medium to regulate the flow or cut off the pipeline control device. This type of valve should generally be installed horizontally in the pipeline. Ventilation butterfly valves are divided into manual, electric and pneumatic transmissions. The actuators can be driven by electric motors or turbines to freely rotate the discs in the 90° range to achieve the purpose of opening and closing or regulating the flow of the medium. The company specializes in producing various specifications of ventilation butterfly valves, the materials are: carbon steel, manganese steel, stainless steel, heat-resistant steel.

Structural butterfly valve structure features

1. Designed and manufactured by the new structural form of welding of mid-line type butterfly plate and short-structure steel plate, compact structure, light weight, easy installation, small flow resistance, large circulation, avoiding the influence of high temperature expansion, and light operation.

2. There are no connecting rods, bolts, etc., reliable operation and long service life. Can be installed in multiple stations, independent of media flow

3. The design is novel, reasonable, unique in structure, light in weight, and quick to open and close.

4, small operating torque, easy to operate, labor-saving and smart.

5. Use suitable materials to meet low, medium and high dielectric temperatures and corrosive media.

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China