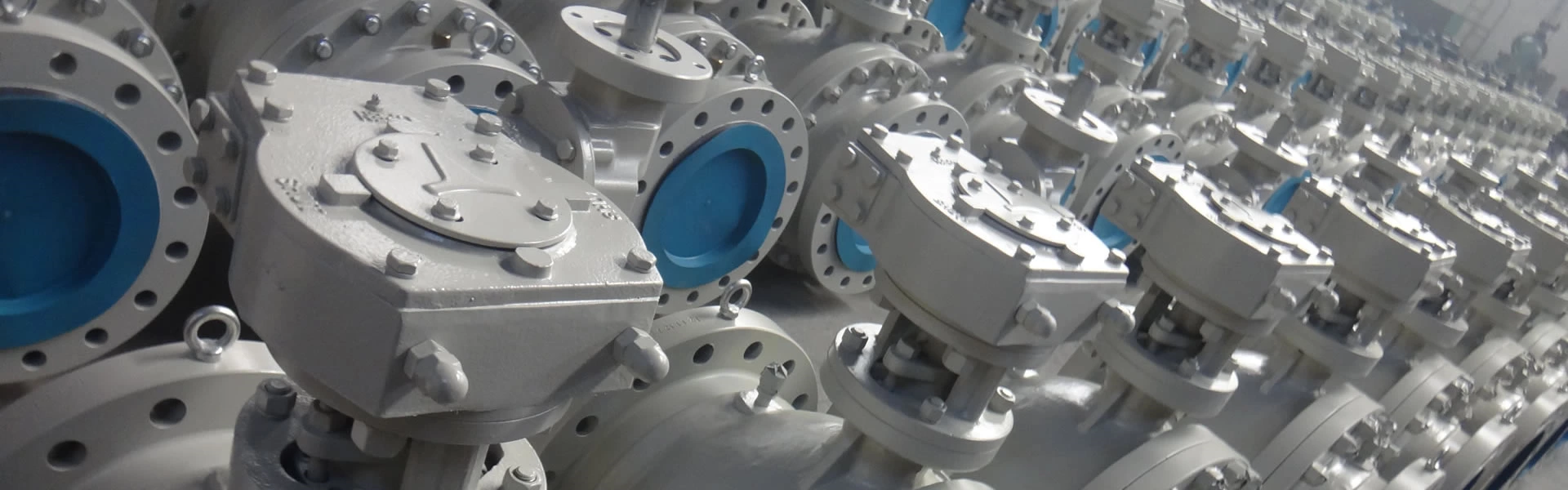

Top Entry Ball Valve

- Size Range

- 2" ~ 48" (DN50~DN1200)

- Temperature Range

- -29°C~+250°C

- Pressure Rating

- 150LB ~ 2500LB (PN10~PN420)

- Operation Type

- Handle, turbine, pneumatic, hydraulic, electric

Specification parameters

| Name | Top Entry Ball Valve |

| Size | 2" ~ 48" (DN50~DN1200) |

| Pressure | 150LB ~ 2500LB (PN10~PN420) |

| Temperature | -29°C~+250°C |

| Body Material | carbon steel, stainless steel, alloy steel |

| Drive Mode | Handle, turbine, pneumatic, hydraulic, electric |

| Applications | Applicable to petroleum, chemical, metallurgy, light industry, power station, urban construction water supply, low temperature working conditions and long-distance pipelines such as oil, water, gas and natural gas |

Design Specification

| Design Standards | API6D, BS 5351, GB/T 12237 |

| Structure length | ASME B16.10, GB/T 12221 |

| Flange Connection Standard | ASME B16.5, ASME B16.47, GB/T 9113, JB/T 79, HG/T 20592 |

| Torsion welding standard | ASME B16.25, GB/T 12234 |

| Fire Protection Requirements | API 6FA, API 607 |

| Pressure test | API 598,GB/T 13927, GB/T 26480 |

| Temperature and Pressure Test | ASME B16.34, GB/T 12224 |

| Design Features | Integral, full bore or reduced diameter, anti-static design, stem anti-flying, fire protection design |

Product Introduction

The top entry ball valve is also called the top-loading ball valve. The integrated valve body at the top into the ball valve reduces the leakage point of the valve. It is convenient for online maintenance, advanced manufacturing process, high pressure and wide application range. The top entry ball valve below DN100 is designed with double bevel structure. Under the action of spring, the ball valve can self-compensate and seal, ensuring good sealing performance at medium and low pressure and long service life. The fixed ball structure is adopted above DN100 to ensure the performance.

1. Integral valve body design, top-loading pivot support, flange construction or butt weld construction.

2, high-intensity integral pivot fixed ball stem design, anti-flying protection structure to ensure the precise positioning of the ball.

3, with double blocking bleed function (DBB function), with fire and anti-static function.

4, 2 or more O-rings, plus the fireproof structure on the stem, to prevent leakage.

5, INCONEL springs move the soft-sealed metal seat money ball with good inlet and outlet two-way sealing function.

6. The standard soft seal (PTFE, RPTFE, DEVLON, NYLON, PEEK) material seat with superior performance ensures effective sealing under low pressure.

7. The sealant injector is designed to inject sealant in an emergency and to seal the stem and seat.

8. Unique valve seat retractable technology, online replaceable stem, ball, stem seal, metal seat and coil spring.

9, location adjustment is convenient. When the actuator is replaced or installed, the position of the ball hole cannot be seen. The company has designed a special "positioning groove" to find the fully open and fully closed position of the ball valve. It is convenient to adjust the limit device of the actuator.

10. For the ball valve whose end is butt welded, the end material (transition section) of the ball valve can be adjusted according to the user's pipe material grade to ensure the material strength and weldability. The length of the sleeves is increased at both ends, and the length of the sleeves ensures that the welding operation on the spot does not affect the sealing material.

11. Buried design. Buried ball valve, the valve stem can be lengthened according to the needs of the project, so that it can be operated on the ground, and the corresponding grease injection, sewage and exhaust devices are extended from the pipe to the ground.

12. Pre-position the drive unit platform and bolt holes to assemble the drive unit required by the customer.

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China