Side Entry Forged Steel Ball Valve

side entry trunnion mounted ball valve,Specification Parameters Name Forged Steel Ball Valve Size 2" ~ 48" (DN50~DN1200) Pressure 150LB ~ 2500LB (PN10~PN420) Temperature -29°C~+250°C Operation Type Turbo, Pneumatic, Hydraulic , Electric Applications Applicable to petroleum, chemical, metallurgy, light industry, power station, urban construction water supply, low temperature working conditions and long-distance

- Size Range

- 2" ~ 48" (DN50~DN1200)

- Temperature Range

- -29°C~+250°C

- Pressure Rating

- 150LB ~ 2500LB (PN10~PN420)

- Operation Type

- Turbo, Pneumatic, Hydraulic , Electric

Specification Parameters

| Name | Forged Steel Ball Valve |

| Size | 2" ~ 48" (DN50~DN1200) |

| Pressure | 150LB ~ 2500LB (PN10~PN420) |

| Temperature | -29°C~+250°C |

| Operation Type | Turbo, Pneumatic, Hydraulic , Electric |

| Applications | Applicable to petroleum, chemical, metallurgy, light industry, power station, urban construction water supply, low temperature working conditions and long-distance pipelines such as oil, water, gas and natural gas |

Design Specification

| Design Standards | API6D, BS 5351, GB/T 12237 |

| Structure length | ASME B16.10, GB/T 12221 |

| Flange Connection Standard | ASME B16.5, ASME B16.47, GB/T 9113, JB/T 79, HG/T 20592 |

| Torsion welding standard | ASME B16.25, GB/T 12234 |

| Fire Protection Requirements | API 6FA, API 607 |

| Pressure test | API 598,GB/T 13927, GB/T 26480 |

| Temperature and Pressure Test | ASME B16.34, GB/T 12224 |

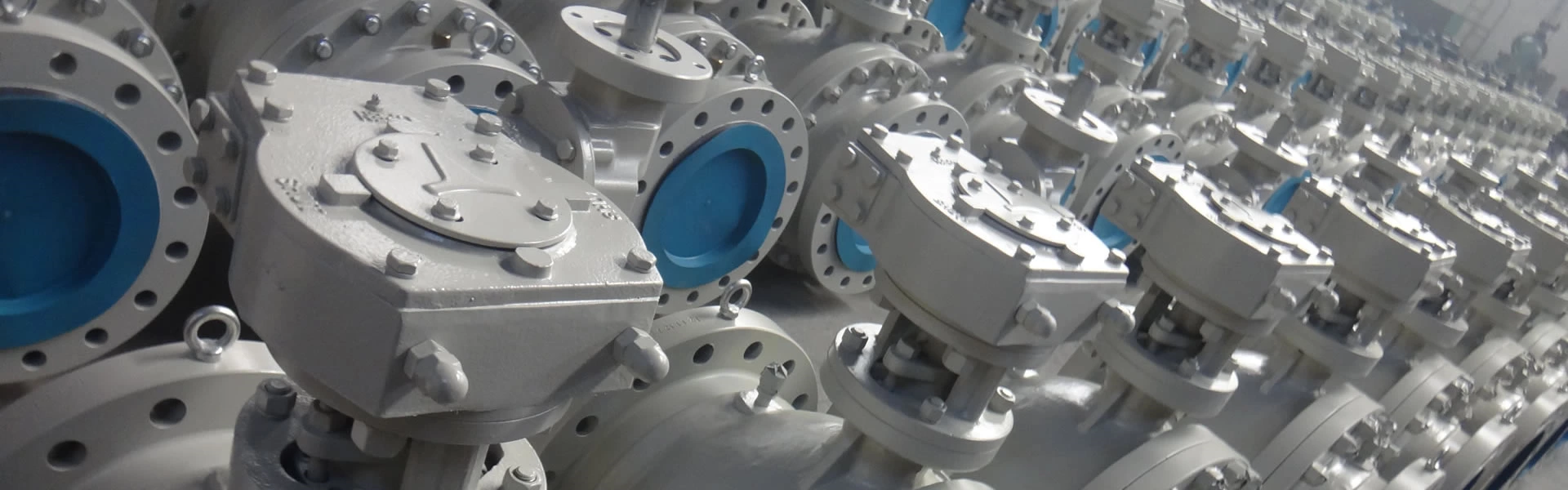

Factory Floor Photos :

Product Introduction:

The body of the forged steel ball valve is forged from high-quality materials, the ball is side-mounted, and the middle flange and neck are bolted. Cast steel fixed ball valve mainly has two-piece and three-piece valve body structure, suitable for general industrial pipelines and long-line pipelines, suitable for various corrosive and non-corrosive media. The user can select the full-diameter or reduced-diameter structure according to the needs. The full-diameter valve flow diameter is consistent with the inner diameter of the pipeline to facilitate pipeline cleaning. According to the customer's requirements, the end connection can be provided as a flange connection and a butt-welded connection. Sleeve can be provided on the welding end as needed; the valve stem lengthened buried all-welded ball valve can be provided according to the customer's working condition. The length of the stem is provided by the customer.

Structural Features:

1, valve seat piston effect, ball valve has three combinations of piston effect: 1, the upper and lower are single piston effect valve seat, that is, DBB function; 2, both upstream and downstream are double piston effect valve seat, namely DIB- 1 function; 3, the upstream is a single piston effect valve seat, the downstream is a double piston effect valve seat, that is, DIB-2 function.

2, the valve seat and the ball are sealed with two structures: one is a traditional soft seal structure, and the other is an advanced combined seal structure.

3. The valve stem anti-flying design, which is the discharge design, prevents the valve stem from being ejected from the valve body due to improper operation.

4. Forged steel ball valves have fireproof and antistatic devices

5. The seat seal and stem seal are designed with an emergency seal grease inlet. The normal seal does not depend on the sealant. When the sealing surface is damaged due to damage, the sealing grease can be injected for emergency repair. A grease injection valve and an inline check valve are installed in each grease injection port.

6. Sewage outlet and exhaust port. A drain valve is installed at the lowest position of the valve body to vent and discharge the valve chamber; an exhaust valve (venting valve) is installed on the valve body, and the valve chamber can be exhausted (empty) and cleaned online. The drain valve and the exhaust valve (venting valve) can be used in the isolation valve or special discharge joint to ensure safety, reliability and convenience.

7. A lands that can be used with various drive units. Including handle, turbine, electric, pneumatic, hydraulic, gas-liquid linkage, electro-hydraulic linkage.

8. Position adjustment is convenient. When the actuator is replaced or installed, the position of the ball hole cannot be seen. The company has designed a special "positioning groove" to find the fully open and fully closed position of the ball valve. It is convenient to adjust the limit device of the actuator.

9. For the ball valve whose end is butt welded, the ball end material (transition section) can be adjusted according to the user's pipe material grade to ensure the material strength and weldability. The length of the sleeves at both ends is large, and the length of the sleeves ensures that the welding operation on the spot does not affect the sealing material.

10, buried design. Buried ball valve, the valve stem can be lengthened according to the needs of the project, so that it can be operated on the ground, and the corresponding grease injection, sewage and exhaust devices are extended from the pipe to the ground.

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China