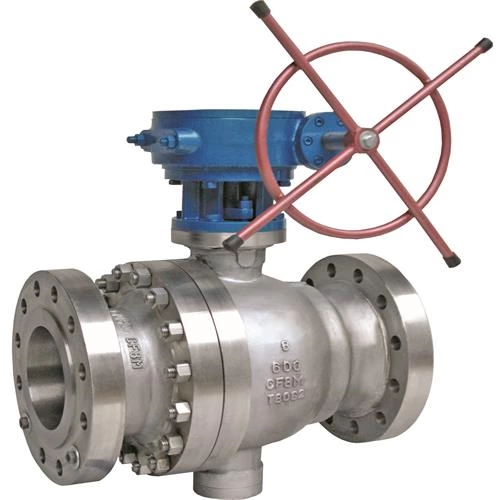

Fully Welded Ball Valve

- Size Range

- 1/2" ~ 48" (DN15~DN1200)

- Temperature Range

- -29°C~+250°C

- Pressure Rating

- 150LB ~ 300LB (PN10~PN40)

- Operation Type

- handle, turbine, pneumatic, electric

Specification parameters

| Name | Full Welded Ball Valve |

| Size | 1/2" ~ 48" (DN15~DN1200) |

| Pressure | 150LB ~ 300LB (PN10~PN40) |

| Temperature | -29°C~+250°C |

| Body Material | carbon steel, stainless steel, alloy steel |

| Drive Mode | handle, turbine, pneumatic, electric |

| Applications | LNG/LPG, petrochemical, steel plant, heating pipe, etc. |

All welded ball valve design specifications:

| Design Standards | API6D, GB/T 12237, GB/T 19672 |

| Structure length | API 6D, ASME B16.10, GB/T 12221 |

| Flange Connection Standard | ASME B16.5, ASME B16.47, GB/T 9113, JB/T 79, HG/T 20592 |

| Torsion welding standard | ASME B16.25, GB/T 12234 |

| Fire Protection Requirements | API 6FA, API 607 |

| Pressure test | API 598,GB/T 13927, GB/T 26480 |

| Temperature and Pressure Test | ASME B16.34, GB/T 12224 |

| Design Features | Full diameter or reduced diameter, anti-static design, stem anti-flying, fire protection design |

Product introduction:

fully welded ball valves include floating ball valves and trunnion ball valves. Large diameter fully welded ball valves generally use trunnion welded ball valves,

The trunnion welded ball valve has a fixed stem on the upper and lower sides of the ball to ensure the stability of the valve when the ball is opened and closed.

Technical characteristics of welded ball valve:

1. The valve body structure is integrally welded without external leakage.

2. The valve seat is made up of PTFE sealing ring and spring. It has strong adaptability to pressure and temperature changes and will not cause any leakage within the scope of use.

3. The anti-leakage structure of the valve stem, a PTFE self-sealing gasket and an O-ring on the bottom of the valve stem. There are two O-rings and two PTFE gaskets on the top to ensure no leakage. .

4. The valve body material is the same as the pipe material, and there will be no uneven stress and no deformation due to earthquake and vehicle passing through the ground.

5, the valve body is light and easy to keep warm.

6. Directly buried ball valve can be buried directly in the ground. It is not necessary to build a large valve well. It only needs to set up a small shallow well on the ground, which greatly saves construction costs and engineering time.

7. The length of the valve body and the height of the valve stem can be adjusted according to the construction and design requirements of the pipeline.

8. The processing precision of the sphere is very precise and easy to operate, without any interference.

10. There are two connection methods of welding and flange.

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China