Core Challenges

Strong corrosion from seawater, high pressure underwater (at the wellhead), and vibration and shock from the platform

Solution

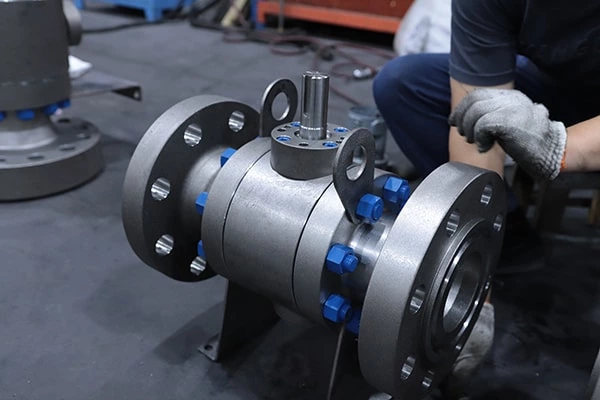

✔ Material: 2205 duplex steel and titanium alloy Gr5 are used underwater

✔ Process: Sandblasting anti-corrosion treatment, static pressure test, and hard alloy surfacing on the sealing surface

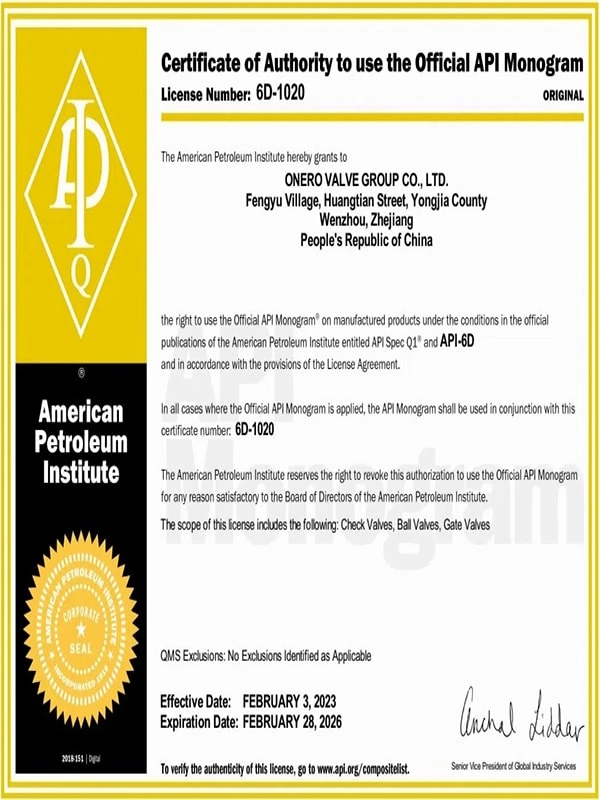

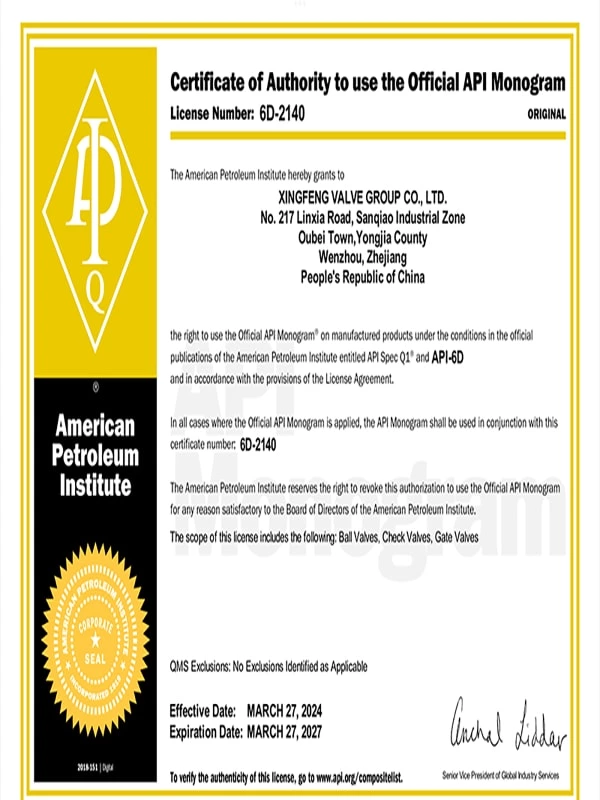

Authorized Certification

API 6A and API 6D certifications