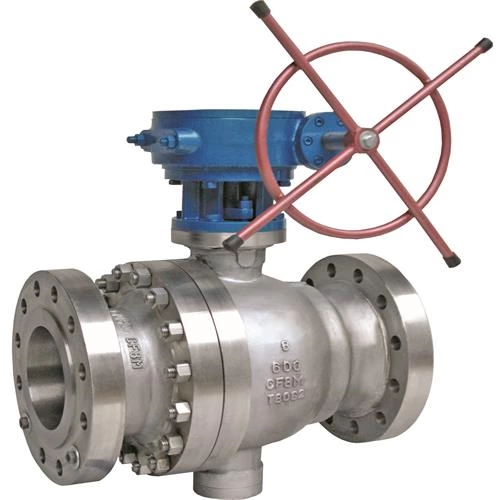

Trunnion Ball Valve

- Size Range

- 2" ~ 48" (DN50~DN1200)

- Temperature Range

- -29°C~+250°C

- Pressure Rating

- 150LB ~ 2500LB (PN10~PN420)

- Operation Type

- Lever, Gear Operated or bare stem

Specification Parameters

| Name | Trunnion Ball Valve |

| Size | 2" ~ 48" (DN50~DN1200) |

| Pressure range | 150LB ~ 2500LB (PN10~PN420) |

| Temperature | -29°C~+250°C |

| Drive Mode | Turbo Operation, Pneumatic Operation, Hydraulic Operation, Electric Operation |

| Applications | Applicable to petroleum, chemical, metallurgy, light industry, power station, urban construction water supply, low temperature working conditions and long-distance pipelines such as oil, water, gas and natural gas |

Design Specification:

| Design Standards | API6D, BS 5351, GB/T 12237 |

| Structure length | ASME B16.10, GB/T 12221 |

| Flange Connection Standard | ASME B16.5, ASME B16.47, GB/T 9113, JB/T 79, HG/T 20592 |

| Torsion welding standard | ASME B16.25, GB/T 12234 |

| Fire Protection Requirements | API 6FA, API 607 |

| Pressure test | API 598,GB/T 13927, GB/T 26480 |

| Temperature and Pressure Test | ASME B16.34, GB/T 12224 |

Product Introduction&Features:

The trunnion ball valve is also called the trunnion ball valve. It is a new generation of high performance ball valve. It is suitable for long-distance pipelines and general industrial pipelines. Its strength, safety and harsh environment are specially considered during design. A corrosive and non-corrosive medium. Compared with the floating ball valve, when working, the force generated by the fluid pressure on the ball before the valve is transmitted to the bearing, and the ball is not moved to the valve seat, so the valve seat does not withstand excessive pressure, so the ball valve is fixed. Low torque, small seat deformation, stable sealing performance and long service life, suitable for high pressure and large diameter applications. Advanced spring pre-seat assembly with self-tightening for upstream sealing. Each valve has two seats that seal in each direction, so the installation has no flow restriction and is bidirectional. This valve is generally installed horizontally.

1) Anti-fire safe design: API 6FA, API607

2) Anti-static device

The static-conduction spring is set between the stem and the ball, the stem and the body. Thus static electricity is conducted to ground and system safety is secured.

3) Anti-blow out design

4) Free leakage of body Sealed construction

The connective position of valve body and bonnet is double sealed by gasket and O-ring, on this base, such factors as fire, high temperature, shock and uneven opening or closing of the torque all can’t induce external leakage

5) Low torque in operation

6) Double block&bleed(DBB)

7) Emergency sealing

8) Automatic body cavity relief

When the body pressure going up un-normally as the unstable factor, the trunnion ball valve downstream seat will be pushed by un-normal pressure, and the release the un-normally pressure automatically, it doesn’t damage to the sealing of upstream seat.

9) The valve structure can be 2 pieces or 3 pieces.

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China